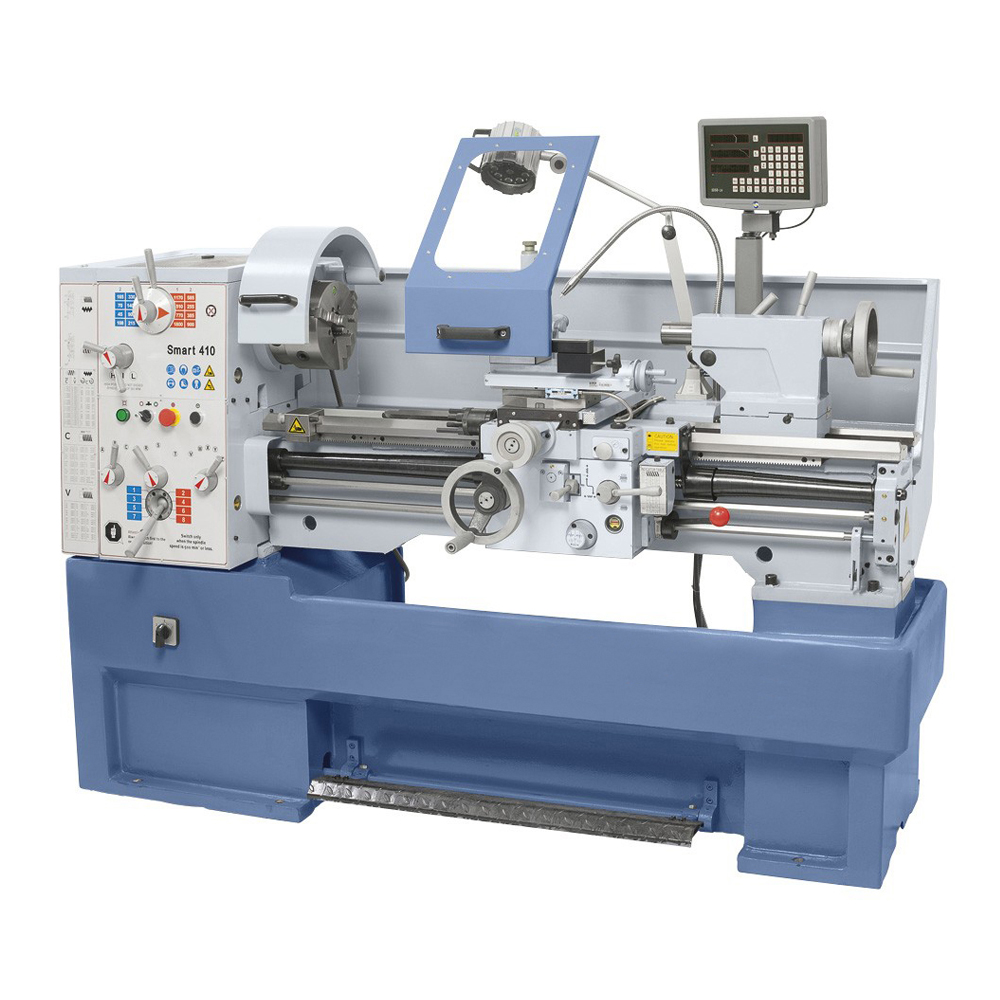

C0632A Bench Lathe Machine

Features

The guide way and all gears in the head stock are hardened and precision ground.

The spindle system is high rigidity and accuracy.

The machines have powerful head stock gear train, high rotating accuracy and smooth running with low noise.

An overload safety device is provided on the apron.

Pedal or electromagnetic braking device.

Tolerance test certificate, test flow chart included

Specifications

| MODELS | C0632A×750 | C0632A×1000 |

| Swing over bed | 330mm(13") | |

| Swing over cross slide | 198mm(7-25/32") | |

| Swing in gap diameter | 476mm(18-3/4") | |

| Swing in length | 210mm(8-1/4") | |

| Center height | 166mm(6-1/2") | |

| Admits between | 750mm(30") | 1000mm(40") |

| Bed width | 187mm(7-3/8") | |

| Bed length | 1405mm(55-5/16") | 1655mm(65-1/8") |

| Bed height | 290mm(11- 13/32") | |

| Spindle bore | 38mm(1-1/2") | |

| Spindle nose | D1-4" | |

| Taper in nose | MT NO.5 | |

| Taper in sleeve | MT NO.3 | |

| Speeds number | 8 | |

| Range of spindle speed | 70-2000 r/min | |

| Cross slide width | 130mm(5-3/32″) | |

| Cross slide travel | 170mm(6-11/16") | |

| Compound rest width | 80mm(3-1/8″) | |

| Compound rest travel | 95mm(3-9/16") | |

| Lead screw diameter | 22mm(7/8″) | |

| Lead screw thread | 8T.P.I. or 3mm | |

| Feed rod diameter | 19mm(3/4") | |

| Cutting tool max section | 16mm×16mm(5/8"×5/8") | |

| Threads imperial pitches | 34 Nos.4-56 T.P.I | |

| Threads metric pitches | 26 Nos.0.4-7 M.P | |

| Longitudinal feeds imperial | 32 Nos.0.002-0.548"/Rev | |

| Longitudinal feeds metric | 32 Nos.0.052-0.392mm/Rev | |

| Cross feeds imperial | 32 Nos.0.007-0.0187"/Rev) | |

| Cross feeds metric | 32 Nos.0.014-0.380mm/Rev | |

| Quill diameter | 32mm(1-1/4") | |

| Quill travel | 100mm(3-15/16") | |

| Quill taper | MT NO.3 | |

| For main motor | 2HP, 3PH or 2PH, 1PH | |

Write your message here and send it to us