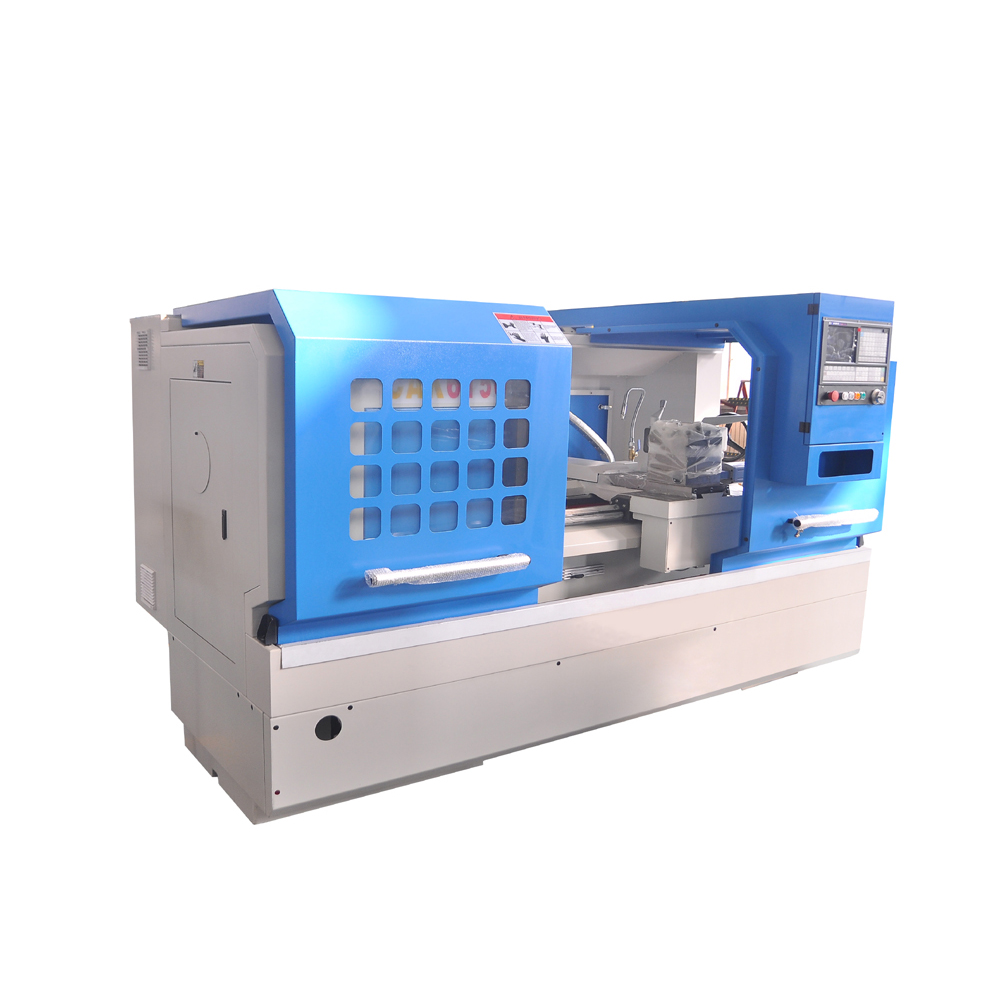

QK1343 CNC Pipe Threading Lathe Machine

Features

1. Able to process inner and outer straight pipe threads and tapered pipe threads with a diameter of 190 millimeters.

2. The lathe is equipped with a taper device that can process a taper of 1:5.

3. It is not necessary to replace the exchange gear to turn metric and imperial threads.

4. The slide box is equipped with a detached worm, which can automatically protect the integrity of the lathe mechanism.

5. The guide rail has undergone quenching, wear-resistant treatment, and precision machining.

6. It has a high power and can withstand heavy loads for powerful cutting.

7. The landing center frame can be moved freely according to user needs, and is equipped with a long pipe clamping adjustment mechanism, greatly reducing labor intensity.

8. There are four jaw chucks in the front and rear of the front trunk, which are suitable for the satisfactory clamping of long and short pipes.

Specifications

|

ITEMS |

UNIT |

QK1343 |

|||

|

Basic |

Max. Dia. swing over bed |

mm |

Φ1000 |

||

|

Max. Dia. swing over cross slide |

mm |

Φ610 |

|||

|

Distance between centers |

mm |

1500 |

|||

|

Range of machining thread |

mm |

Φ270-430 |

|||

|

Width of bed way |

mm |

755 |

|||

|

Main motor |

kw |

22/37 |

|||

|

Coolant pump motor |

kw |

0.125 |

|||

|

Spindle |

Spindle bore |

mm |

Φ440 |

||

|

Spindle speed (frequency conversion) |

r/min |

3 steps: 10-60 / 60-100 / 100-200 |

|||

|

Tool post |

Number of tool stations |

-- |

4 |

||

|

Size of tool section |

mm |

40×40 |

|||

|

Feed |

Z axis servo motor |

kw/Nm |

GSK:2.3/15 |

Fanuc:2.5/20 |

Siemens:2.3/15 |

|

X axis servo motor |

kw/Nm |

GSK:1.5/10 |

Fanuc:1.4/10.5 |

Siemens:1.5/10 |

|

|

Z axis travel |

mm |

1250 |

|||

|

X axis travel |

mm |

500 |

|||

|

X/Z axis rapid traverse speed |

mm/min |

4000 |

|||

|

Number of feed and screw pitch |

mm |

0.001-40 |

|||

|

Accuracy |

Positioning accuracy |

mm |

0.020 |

||

|

Repositioning accuracy |

mm |

0.010 |

|||

|

CNC system |

GSK |

-- |

GSK980TDC |

||

|

Fanuc |

-- |

Fanuc Oi Mate TD |

|||

|

Siemens |

-- |

Siemens 808D |

|||

|

Tailstock |

Tailstock quill diameter |

mm |

Φ140 |

||

|

Tailstock quill taper |

mores |

m6# |

|||

|

Tailstock quill travel |

mm |

300 |

|||

|

Tailstock cross travel |

mm |

±25 |

|||

|

Others |

Dimension(L/W/H) |

mm |

5000×2100×2100 |

||

|

Net weight (kg) |

kg |

13000 |

|||

|

Gross weight |

kg |

14500 |

|||

|

Accessory |

Tool post |

1 set |

4 position NC turret |

||

|

Chuck |

2 set |

Φ1000 four-jaw electric chuck |

|||

|

Center rest |

-- |

negotiate if necessary |

|||

|

Rear support bracket |

-- |

negotiate if necessary |

|||

|

Package |

Standard export package |

1 set |

Steel pallet iron frame and plywood box |

||