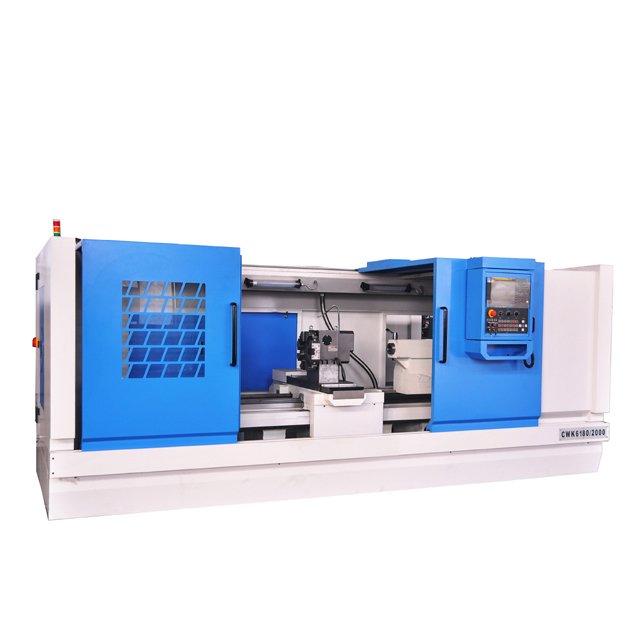

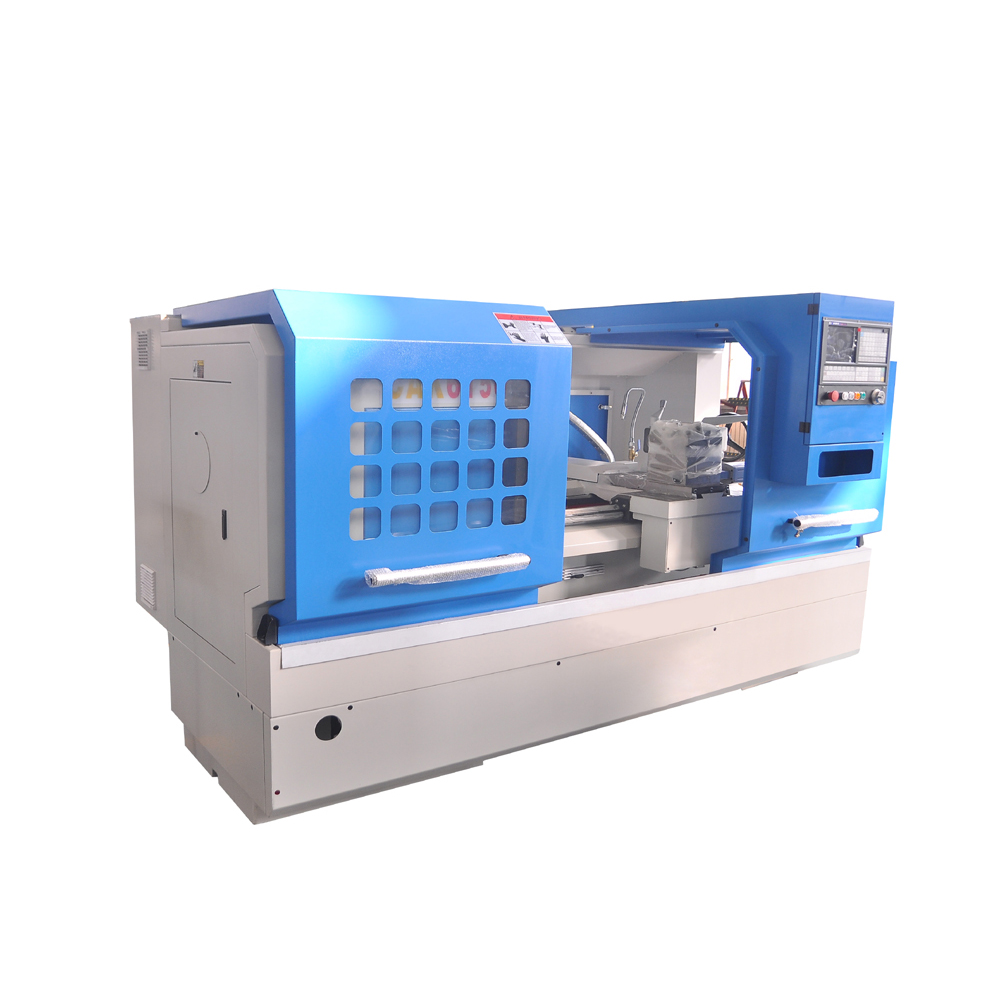

Slant Bed CNC Precision Lathe TCK6340

Features

1.1The whole machine has compact structure, beautiful and pleasant appearance, large spindle torque, high rigidity, stable and reliable performance, and excellent precision retention.

1.2 Adopt 45° overall inclined bed structure, equipped with high-precision preload Taiwan linear rolling guide, the machine tool has high position accuracy, smooth chip removal, suitable for high-speed and high-precision machining.

1.3 The spindle with high-precision spindle bearing set and precision assembly and dynamic balance test ensures high precision, low noise and strong rigidity of the spindle.

1.4 The turret mode is selected, the tool change speed is fast, and the positioning accuracy is high.

1.5 The X and Z feeds are directly connected to the lead screw by a servo motor through a high-torque low-inertia elastic coupling to ensure positioning accuracy and repeat positioning accuracy.

1.6 The use of advanced centralized automatic lubrication device, timing, quantitative automatic intermittent lubrication, stable and reliable work.

1.7 Adopt domestic hydraulic chuck.

1.8 The protection of the machine tool adopts the full protection design, which is pleasant, strong, waterproof and anti-chip, reliable, and easy to maintain.

Specifications

| Specification | Unit | TCK6340 |

| Max. swing over bed | mm | 400 |

| Max. swing over cross slide | mm | 140 |

| Max. processing length | mm | 300 |

| X/Z axis travel | mm | 380/350 |

| Spindle unit | mm | 170 |

| Spindle nose | A2-5 | |

| Spindle bore | mm | 56 |

| Spindle drawing pipe diameter | mm | 45 |

| Spindle speed | rpm | 3500 |

| Chuck size | inch | 6/8 |

| Spindle motor | kw | 5.5 |

| X/Z repeatability | mm | ±0.003 |

| X/Z axis feed motor torque | N.m | 6/6 |

| X/Z rapid traverse | m/min | 18/18 |

| Tool post type | Gang type tool post | |

| Cutting tool shape size | mm | 20*20 |

| Guide form | 45° inclined guide rail | |

| Total power capacity | kva | 9/11 |

| Machine dimension (L*W*H) | mm | 2300*1500*1750 |

| N.W. | KG | 2500 |