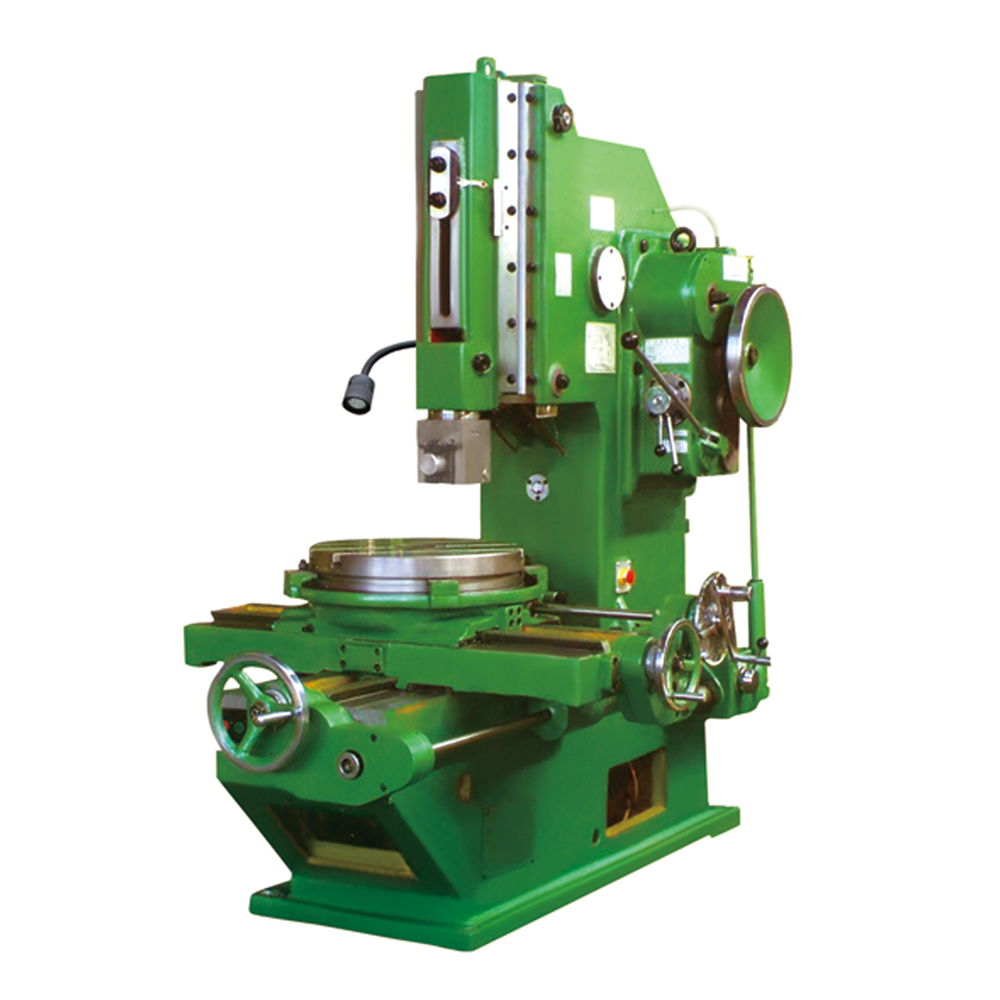

Vertical Slotting Machine B5032

Specifications

|

SPECIFICATION |

B5020D |

B5032D |

B5040 |

B5050A |

|

Max slotting length |

200mm |

320mm |

400mm |

500mm |

|

Max dimensions of workpiece (LxH) |

485x200mm |

600x320mm |

700x320mm |

- |

|

Max weight of workpiece |

400kg |

500kg |

500kg |

2000kg |

|

Table diameter |

500mm |

630mm |

710mm |

1000mm |

|

Max longitudinal travel of table |

500mm |

630mm |

560/700mm |

1000mm |

|

Max cross travel of table |

500mm |

560mm |

480/560mm |

660mm |

|

Range of table power feeds (mm) |

0.052-0.738 |

0.052-0.738 |

0.052-0.783 |

3,6,9,12,18,36 |

|

Main motor power |

3kw |

4kw |

5.5kw |

7.5kw |

|

Overall dimensions (LxWxH) |

1836x1305x1995 |

2180x1496x2245 |

2450x1525x2535 |

3480x2085x3307 |

Safety Regulations

1. The wrench used must match the nut, and the force should be appropriate to prevent slipping and injury.

2. When clamping the workpiece, a good reference plane should be selected, and the pressure plate and pad iron should be stable and reliable. The clamping force should be appropriate to ensure that the workpiece does not loosen during cutting.

3. The workbench with linear motion (longitudinal, transverse) and circular motion is not allowed to perform all three simultaneously.

4. It is prohibited to change the speed of the slider during operation. After adjusting the stroke and insertion position of the slider, it must be locked tightly.

5. During work, do not extend your head into the stroke of the slider to observe the machining situation. The stroke cannot exceed the machine tool specifications.

6. When changing gears, changing tools, or tightening screws, the vehicle must be stopped.

7. After the work is completed, each handle should be placed in a vacant position, and the workbench, machine tool, and the surrounding area of the machine tool should be cleaned and tidy.

8. When using a crane, the lifting equipment must be firm and reliable, and it is not allowed to operate or pass under the lifted object. Close cooperation with the crane operator is necessary.

9. Before driving, inspect and lubricate all components, wear protective equipment, and tie the cuffs.

10. Do not blow iron filings with your mouth or clean them with your hands.