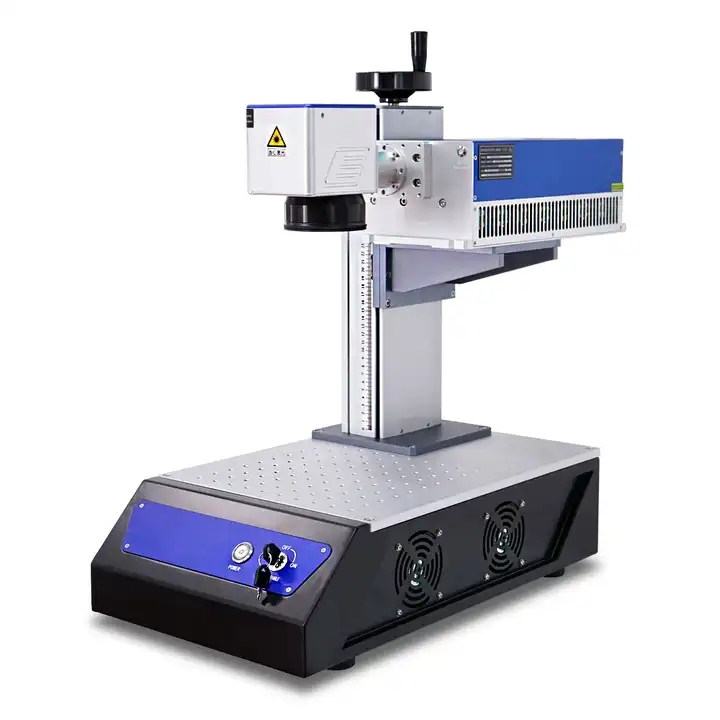

DK7732HC DK7740HC DK7750HC Wire cutting machine

Features

The use of frequency converter to achieve wire speed stepless adjustment , to achieve smooth operation with low noise.

●Run wire using PLC control to achieve variable stroke reciprocating wire , forward and reverse travel to any set.

●Realize non-stripe cutting , improve the surface machining quality of workpiece.

Specifications

| Type | Unit | DK7732HC | DK7740HC | DK7750HC |

| Work table | mm | 370X610 | 480x720 | 580X880 |

| Travel of X/Y Axis | mm | 300X400 | 400X500 | 500x600 |

| Max. cut thickness of Z axis | mm | 300 | 300 | 350 |

| Travel of U/V Axis | 60x60 | |||

| Diameter of Mo.wire | mm | Molybdenum wire Ø0.12-0.18 | ||

| Wire speed | 7seps | |||

| Taper angle/workpiece thickness | °/mm | 3°/60mm | ||

| Process accurary(vertical) | mm | Multi-cut 10x10x30 Squire≤0.006 One cut≤0.012 Octagon≤0.009 |

||

| Process roughness | μm | Multi-cut:Ra≤1.2 One cut: Ra≤2.5 | ||

| Motor drive system | Stepper motor (Option:Servo motor) | |||

| Screw/Guides (X,Y) | Precision ball screw/linear Motion guides | |||

| Wire tension | Precision spring automatic tensioning | |||

| Working fluid/capacity | L | Complex or water-dissovie special coolant/65L | ||

| Power supply | kw | 2 | ||

| Max. load weight | kg | 300 | 400 | 500 |

| Net weight | kg | 1900 | 2200 | 2500 |

| Dimensions | mm | 1800x1150x2120 | 1950x1350x2150 | 2100x1500x2300 |

Write your message here and send it to us