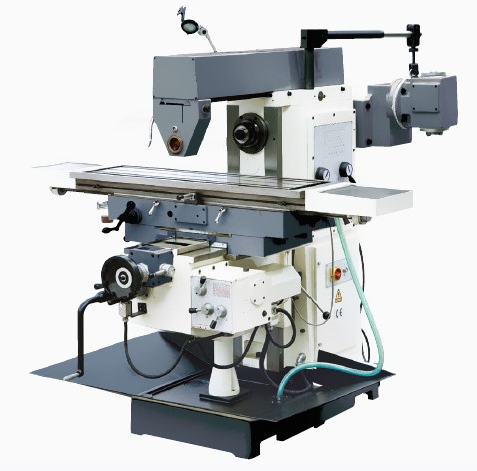

XH7145 CNC Vertical Machining Center

Features

1. XH7145A Machine center's base, slide, worktable, column, spindle and other main parts applicated high rigid cast iron structure, guarantee the main parts' high rigid and anti-vibration. The main parts all adopted by resin sand and aging treatment, assuring the stability of the machine

2.X,Y, Z-axis adopted linear rolling guide rail, eliminating the feeding friction resistance and low speed creep, longer machine precision life.

1..X, Y, Z-axis adopted famous brand high precision ball lead screw, resulted high rapid speed and high positional accuracy.

2.X, Y, Z-axis guide way and lead screws adopted full confined protection, assuring the cleaness of lead screw and guide way as well asmachine's transmission and motion precision.

3.The outside protection of the machine is full-closed structure, guarantee the safety. semi-closed protection is also available. .

4.XH7145A CNC milling machine center tool operation system by the principle of human body engineering design, easy operation.

5.XH7145A CNC milling machine center Manual central lubrication and high stability.

6.Famous CNC system, FANUC, KND, SIEMENS, MITSUBISHI for your choices.

Specifications

| MODEL | UNIT | XHS7145 | XH7145A | XK7145A |

| X-axis travel | mm | 600 | 700 | 700 |

| Y- axis travel | mm | 450 | 450 | 450 |

| Z- axis travel | mm | 500 | 500 | 500 |

| Spindle nose to table | mm | 130-630 | 120-620 | 120-620 |

| Spindle center to column guide-way face | mm | 485 | 460 | 460 |

| High speed feeding of X,Y, axis | mm/min | 24000 | 12000 | 12000 |

| High speed feeding of Z axis | mm/min | 18000 | 10000 | 10000 |

| Feeding speed | mm/min | 1-5000 | 1-5000 | 1-5000 |

| Size of table | mm | 1000x450 | 1000x450 | 1000x450 |

| Max. loading capacity of table | kg | 600 | 600 | 600 |

| T-slot NO./width /distance of table | 3/18/160 | 5/18/80 | 5/18/80 | |

| Spindle max. speed | r/min | 8000 | 8000 | 8000 |

| Main motor rated power | kw | 5.5/7.5 | 5.5/7.5 | 5.5/7.5 |

| Spindle nose taper | BT40 | BT40 | BT40 | |

| ax. diameter of tools | mm | 80/130 | 80/130 | - |

| Max. length of tools | 300 | 300 | - | |

| Max. weight of tools | kg | 6 | 6 | 6 |

| Positioning accuracy | mm | 0.025(GB)0.016(Real) | 0.025(GB)0.016(Real) | 0.05(GB)0.02(Real) |

| Re-positioning accuracy | mm | 0.015(GB)0.008(Real) | 0.015(GB)0.01(Real) | 0.02(GB)0.012(Real) |

| Pneumatic press | mpa | 0.6 | 0.6 | 0.6 |

| N.W | kg | 3500 | 3500 | 3400 |

| Overall dimension | mm | 2500x2000x2450 | 2500x2000x2450 | 2500×2000×2450 |